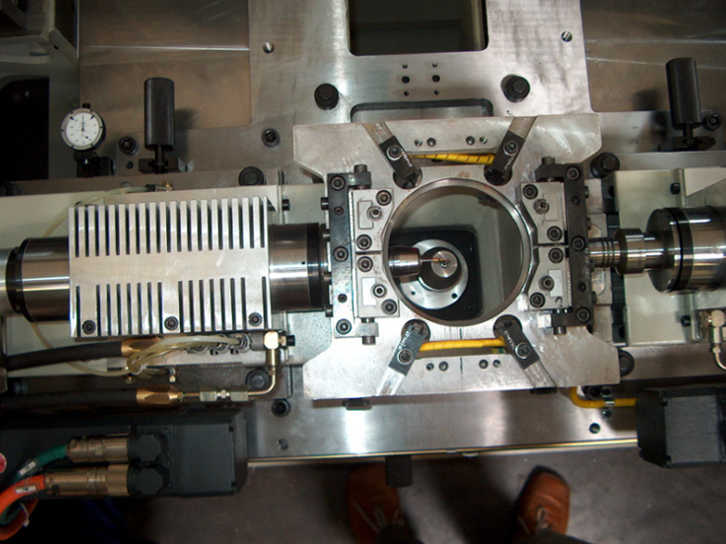

Special boring machine

To construct and build a high efficient production unit for small parts, was an

additional task for the company Stadler. Below you can see the solution conducted

for this customer wish.

With the two vibrating conveyors, the work pieces will be brought into position

for the loading via robot. The two robots, both equipped with a chuck, will unload

the parts out of the unload-position and place them into the scroll chuck station

which serves as machining station too. Two boring spindles facing each other will

machine two nozzle borings simultaneously. For cycle time reasons the machining

will be alternating. As next step the resulted internal ridge will be removed by

a vertical boring spindle. After this machining the robot will position the parts

on a pallet. The cycle time was 3 sec.